Value Stream Mapping (VSM) is one of the most practical tools in Lean. It shows how work actually moves through a system — not how we think it moves. It captures both material flow and information flow, and it forces leaders to see where time, effort, and risk accumulate.

In an industrial setting like an NGL fractionator, and in a service process like issuing safe work permits, the principles are exactly the same. Value either flows — or it waits.

Using VSM in an NGL Fractionator

In an NGL fractionation facility, the customer value is clear: safely separated, on-spec products delivered reliably and at cost.

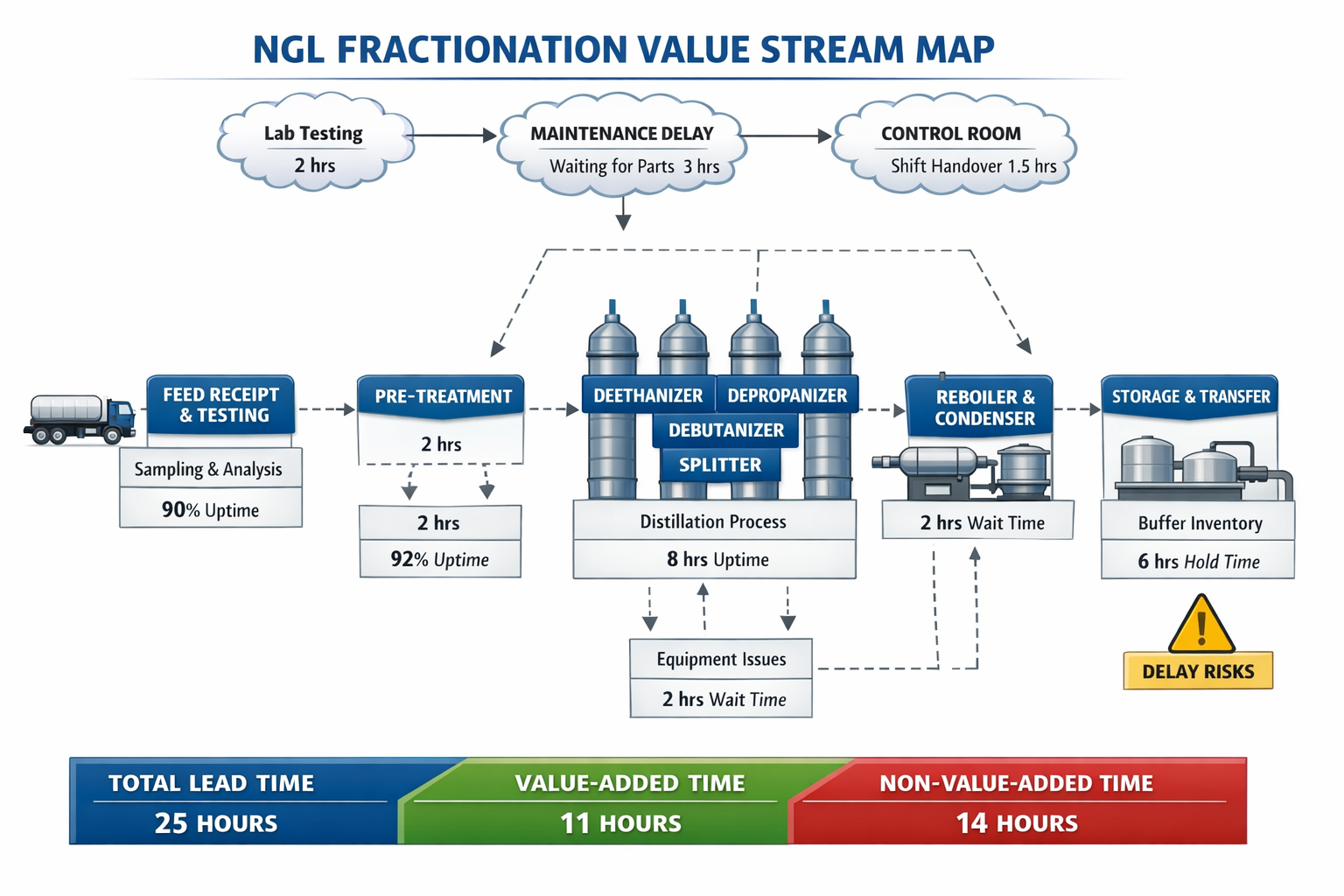

On paper, the process appears continuous. Feed enters. Columns separate. Products leave storage. But when you map the current state honestly, the delays become visible.

You may find:

- Analyzer delays before product release

- Waiting on maintenance for pumps or reboilers

- Shift handoff gaps between field and control room

- Lab rework due to unclear sampling standards

- Intermediate storage acting as a buffer for instability

A Value Stream Map measures total lead time from feed entry to finished product shipment. Then it compares that to actual value-added processing time. The gap between those two numbers is where opportunity lives.

In many plants, the majority of lead time is not active separation. It is waiting, stabilizing, correcting, or communicating.

That waiting is not harmless. When flow is unstable, operators rush to recover. Maintenance gets reactive. Supervisors firefight instead of improving. Instability increases both cost and safety exposure.

Mapping the value stream makes constraints and bottlenecks visible. It shows whether your true limitation is column capacity, lab turnaround, mechanical reliability, or decision-making speed.

You cannot improve what you have not clearly seen.

Using VSM in Safe Work Permitting

Now consider a service line: the safe work permit process.

The “product” here is authorized, hazard-assessed work performed without incident. The customer may be maintenance, operations, or contractors. The value is controlled risk and safe execution.

A current state map typically includes work request, supervisor review, job safety analysis, gas testing, drafting, approval routing, field verification, execution, and closeout.

When mapped with real data instead of assumptions, common issues appear:

- Permits sitting in approval queues

- Rework due to incomplete hazard analysis

- Crews waiting on gas tests

- Multiple signatures that add time but not clarity

- Poor visibility into permit status

In many facilities, the crew’s waiting time exceeds the actual task time. That waiting creates frustration, overtime, and pressure. Pressure tempts shortcuts. Shortcuts create exposure.

Value Stream Mapping does not remove safety steps. It clarifies them. It separates what truly reduces risk from what simply adds delay.

When the permit process flows smoothly, three things happen:

- Work begins on time.

- Supervisors are less reactive.

- Safety compliance improves because it is easier to follow the process than to bypass it.

Flow supports safety. It does not compete with it.

Why This Matters

Value Stream Mapping is not about drawing boxes. It is about leadership visibility.

In a fractionator, poor flow increases cost and operational risk.

In permitting, poor flow increases frustration and behavioral risk.

Both systems depend on clear information, defined handoffs, and disciplined execution.

When you map both production flow and safety flow, a larger truth often emerges: they reflect the same culture. If communication is slow in operations, it is usually slow in permitting. If accountability is unclear in maintenance planning, it is usually unclear in permit approvals.

Lean improvement begins with seeing the whole system.

Practical Takeaway

If you lead in an industrial environment:

- Map one production value stream from start to finish.

- Map one service value stream, such as permitting.

- Measure actual lead time, not assumed time.

- Identify where work waits.

- Remove barriers that do not add value or reduce risk.

The goal is not speed for its own sake. The goal is stable, predictable flow that protects people and delivers results.

When value flows well, production stabilizes, safety strengthens, and people experience less friction in their daily work.

That is what Value Stream Mapping is ultimately for.